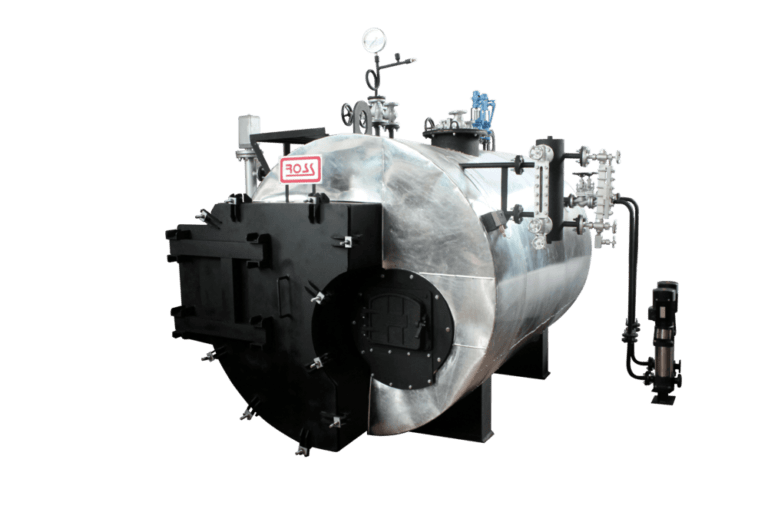

Boilers for Textile Industry

Process Heat experts

Boilers for Textile Industry generate high-quality steam for essential processes in textile manufacturing, such as dyeing and finishing. Designed for durability and efficiency, these boilers feature advanced controls and energy-efficient operations. They ensure consistent steam quality and support high performance while maintaining hygiene standards in textile production.

Delivering top-tier steam boilers and heating solutions worldwide.

Manufacturing excellence for global supply of process heating equipment.

Offering consultations globally to enhance your industrial heating systems.

Steam Boiler Manufacturer and High-Quality Process Heating Equipment

Who we are

Boilers for Textile Industry

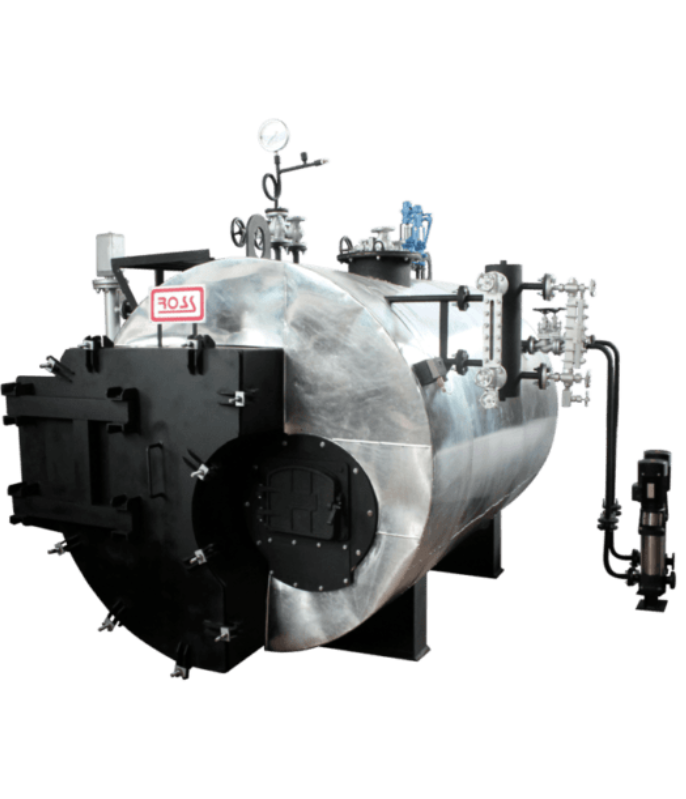

Textile boilers are essential for the textile industry, providing high-quality steam needed for processes such as dyeing, finishing, and fabric treatment. These boilers are specifically designed to meet the rigorous demands of textile manufacturing, ensuring consistent performance and reliability. Built with durable materials, they can withstand the high temperatures and continuous use typical of textile operations. Advanced control systems enable precise regulation of steam output, optimizing the efficiency of each production stage.

Additionally, these boilers are engineered for energy efficiency, reducing fuel consumption and operational costs while minimizing environmental impact. Maintaining steam purity is crucial in textile processing, and these boilers feature designs that ensure clean, uncontaminated steam, meeting strict hygiene standards. By enhancing operational efficiency and product quality, textile steam boilers play a vital role in supporting the effective and sustainable production of textiles.

Join our satisfied customers from over 50 countries.

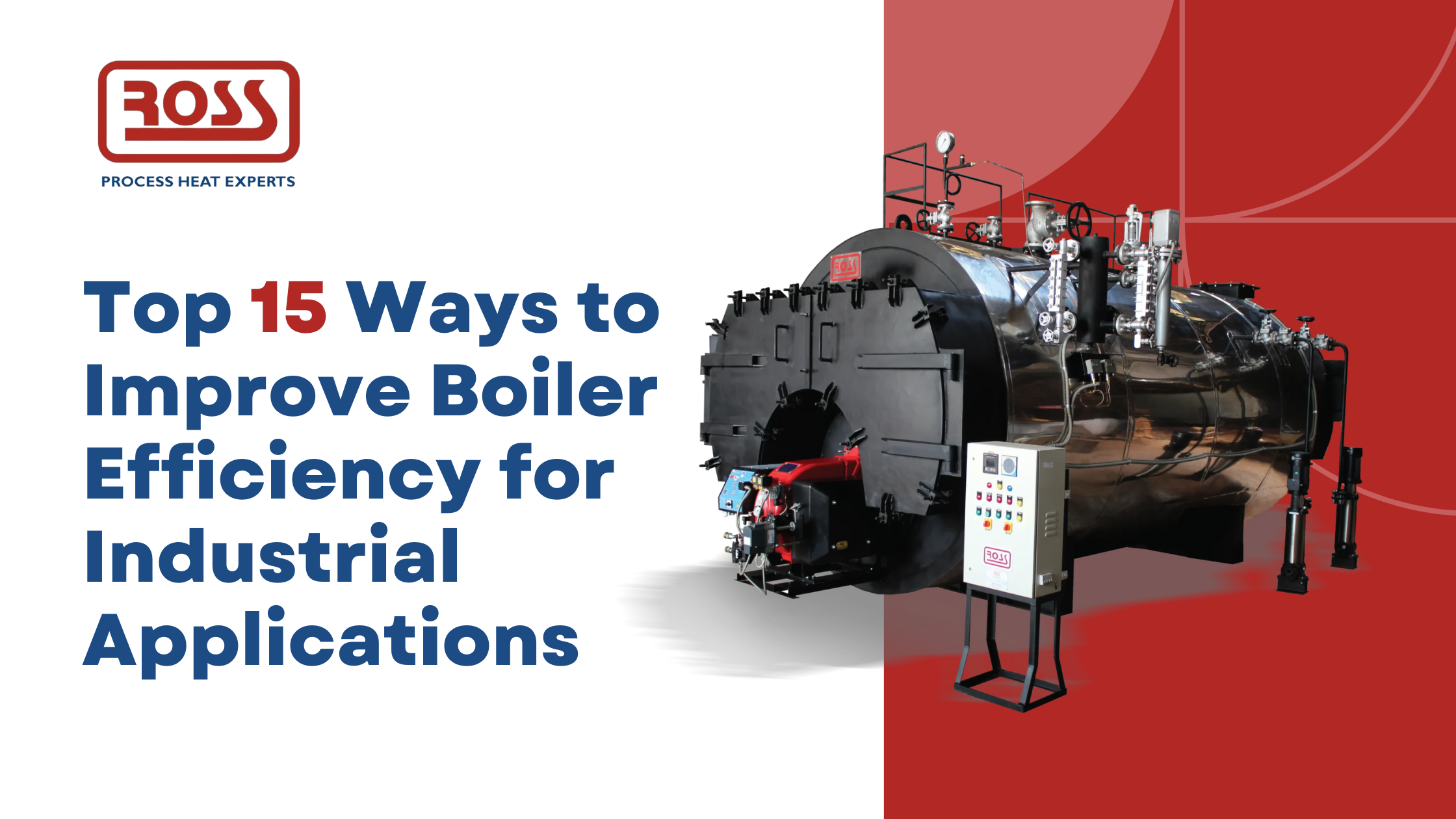

Why Choose Ross Boilers?

Ross Boilers has over 30 years of experience in manufacturing Reliable and efficient boilers.

We have more than 5000 satisfied customers in over 50 countries across 5 continents.

State of the art manufacturing facility, Prompt and responsive after-sales service

From the basic hot water generator, we have expanded our product line to include industrial steam boilers, thermic fluid heaters, hot air generators, waste heat recovery units, burners, water softeners & various other boiler accessories.

We have an excellent reputation for the quality of our product range & after-sales service.

Our Products

Our Prominent Clients

Frequently Asked Questions

Key features include efficient steam generation, durable construction, advanced control systems, energy efficiency, and hygienic operation to ensure clean steam.

High-quality steam is crucial for achieving consistent results in dyeing and finishing processes. Contaminated steam can affect fabric quality and processing efficiency.

Consider factors such as steam capacity, energy efficiency, durability, and specific operational needs. Consulting with a boiler expert can help you select the most suitable model for your requirements.

Yes, they can be customized to meet various needs, including specific steam capacities, operational features, and sizes to fit different types of textile processing operations.

Yes, many modern textile steam boilers are designed to be energy-efficient, reducing fuel consumption and operational costs while maintaining high performance.

WE EXPORED TO MORE THAN 50 COUNTRIES ACROSS 5 CONTINENTS

We are here to assist you with your Boiler requirements. For inquiries, quotes, or any other information, please reach out to us :